Increasing workplace safety and eliminating live work around high-pressure valves with the new Komatsu Valve Adjustment Device (K-VAD)

Düsseldorf, January 2024 – The Mining Division of Komatsu Germany (KGM) is launching K-VAD, a cutting-edge tool designed to facilitate the safe and secure adjustment of main and secondary relief valves on hydraulic mining excavators.

With a focus on enhancing workplace safety and eliminating live work, the K-VAD allows for remote operation from within the operator cabin, eliminating the need for service engineers to work next to high-pressure areas. This increases safety in the workplace and prevents work on the running machine in the high-pressure area.

Key features of the Komatsu Valve Adjustment Device

Complete equipment just in one tool kit

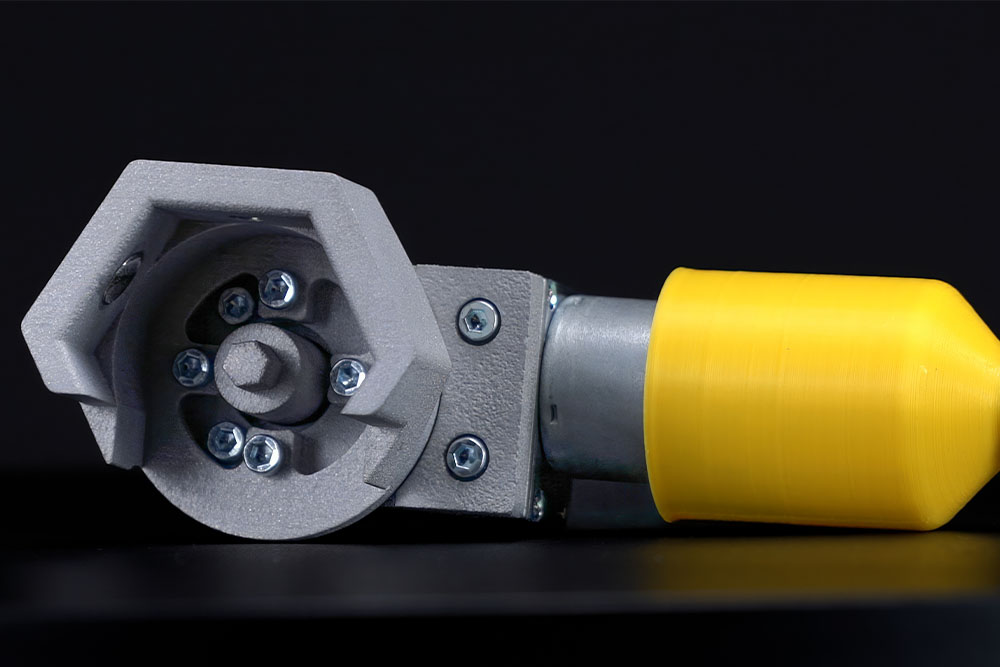

K-VAD is supplied complete in a tool kit. It can be operated via Wi-Fi or via the 7-inch touchscreen. The set includes everything needed for valve adjustment: pressure sensors, adjustment motors with tool heads and allen keys.

Wide range of operating options

The device can be operated by laptop, tablet, or smartphone. It enables the control of up to six tool heads and displaying up to four pressures. Moreover, the engine power check can be carried out with the K-VAD tool.

Smart and durable design

Thanks to their smart design, the K-VAD tool heads can be attached to the valves from different angles. The K-VAD controller is operated via a 7-inch LCD touch display, is dust and splash-proof as the entire K-VAD tool kit.

Exclusively developed at KGM in Germany

The K-VAD user interface and the controller’s firmware have been exclusively developed in-house by the Mining Division of Komatsu Germany, emphasizing the company’s commitment to ongoing innovation. Future updates, including the automation of the adjustment process, are in the pipeline, along with the development of new tool heads for adjusting additional hydraulic circuits.

Use for further Komatsu mining machines

The K-VAD is applicable for all Komatsu hydraulic mining excavators ranging from machine models PC3000 up to PC8000. With safety at the forefront, eliminating live work in high-pressure areas is a core priority at Komatsu. That’s why Komatsu is also exploring the development of additional tool kits to adjust the hydraulic systems of other products such as dump trucks and wheel loaders.

Contact in Germany:

Jens Klopmeier

Komatsu Germany GmbH - Mining Division

Manager CI & Operator Training

Mail: jens.klopmeier@komatsu-mining.de

Office: Forststraße 29, 40597 Düsseldorf